- Home

- Company

- Industries

- Pharmaceutical Industries

- Food and Chemical Industries

- Agro industry

- Cement Industries

- Foundry Industry

- Petrochemical Industry

- Detergent Industry Insights: Sparking Innovation

- Steel & Non-Ferrous Industries

- Distillary & Brewery Industries

- Biscuit and Confectionary

- Fertilizer Industry

- Polymer Industries

- Systems

- Products

- Life At Rajdeep

- Contact Us

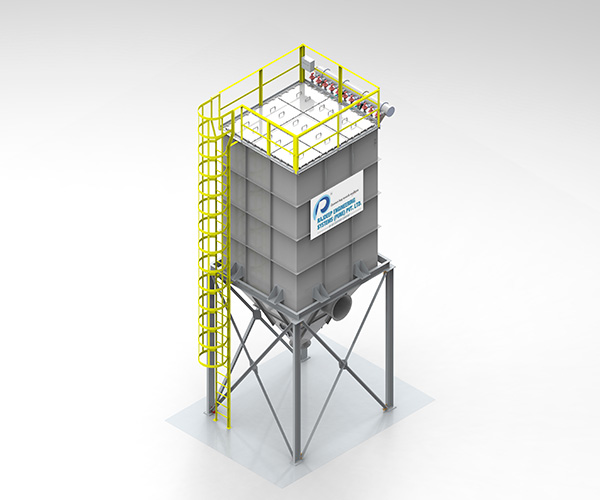

Bag Filter/Dust Collector

Unlock Cleaner Air: Bag Filter Experts Transforming Spaces

RAJDEEP has been involved in providing our clients with a wide range of Bag Filters to maintain a clean & green environment.

Dirty gas enters from the bottom of the bag house and flows from outside to inside the bags. Bags are cleaned by a short burst of compressed air injected through a common manifold over a row of bags. The compressed air is accelerated by a venturi nozzle mounted at the top of the bag. Since the duration of the compressed-air burst is short (0.1s), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex.

This flexing of the bags breaks the dust cake, and the dislodged dust falls into a storage hopper below.

Advantages:

- Have a high collection efficiency of dust.

- Can have high air-to-cloth ratio (0.8 to 1.4 m3/min/m2)

- Have increased efficiency and minimal residual dust build-up due to aggressive cleaning action.

- Can clean continuously

- Have lower bag wear

- Have small size and fewer bags because of the high air-to-cloth ratio

- Some designs allow bag changing without entering the bag house

- Have low-pressure drop for equivalent collection efficiencies

Type of Bag Filter

- Dust Collector

- Cyclone Dust Collector

- Pulse Jet Bag Filter

- Vent Filter

- Silo Top

- Product Separator

- Pleated Bag Filter

- Gas Cleaning Plant.

Features:

German-Inspired Reverse Pulse Jet Filtration Technology: Our vapor clearing stations use the most modern method of formation of German engineering which is both responsive and progressive spin cleaning of air filters.

Opti-Air™ Precision Pulsing System: Using the adaptable timed-on technology of the Opti-Air™ device, the machine enables pulsation frequency optimization, balancing the DP and keeping the suction activity at the point of extraction uniform.

Enhanced Performance Through Computational Analysis: The applied CFD simulators consist of a technical tool to help us improve our bag filter systems which we use for removing the dust.

Expertise in Filter Media Across Industries: Along with more than 45 years of industry background, we’ve built up unrivaled knowledge that covers a variety of filter media material insights.

Premier In-House Cage Fabrication: The best quality cages are produced using the high-tech assembly line, putting accuracy characteristics into play such as concentricity, perfect welding, wire precise readability, and fitting of collars and ventures.

Cutting-Edge Rotary Air Lock Valve Manufacturing: Our advanced workshop in the city of Alandi would require us to manufacture excellent components for filter bag valves, a critical factor in the efficient operation of the machine. We have developed a unique process of manufacturing, which includes making a rotor and housing very solid with the use of precision machining, and shafts, as well as paying much attention to assembly and testing, so the resulting system reaches the highest performance level.

ACGIH Standard Compliant Solutions: Both our equipment and dust extraction systems are designed according to the latest ACGIH standards and specifications; therefore, all our equipment is fire and dust-proof.

Tailored On-Site System Evaluations: During business visits, we evaluate arrays that have specific difficulties or important task failures, offering a filtration system that addresses your specific needs.

Exceptional Emission Reduction Capabilities: Our systems operate to the extent that minimizes pollution that could affect work zones by as low as 1-2 mg/Nm^3 therefore enhancing air quality and stirring the public to high-quality air.

Modular Bag Filter Design: In that way, making a bag from one piece, but by doing Plenum, Casing/Housing, and Hopper components, we made the product reproducible, easily assembled, and maintained.

High-Efficiency Filtration: Clean safe air becomes possible thanks to superb air filtration that can catch even submicron-sized particles that our systems can produce.

Baffle Plate Integration: Our design approach created the option of the separation of incoming, highly-dusted gases thanks to the baffle plate which acts as a shield for the filter bag’s rotation from direct exposure to the gas stream, thus improving the collection point.

Automated Self-Cleaning Function: Dirt trail-off from filter bags is herewith reduced, and filtration effectiveness is maintained, as a result of an automatic filter bag cleaning machine that comes as a standard feature.

Optimized for Lower Utility Usage: Our micro modeling, allows the utility bill to be lowered without compromising on performance and as the operation couldn’t scale, the cost will be reduced eventually.

Robust System Construction: Developed to operate in different industrial conditions during its use process, the systems have greater chances of longer service life.

Custom-Fit Ductwork Solutions: We deal with software that provides solutions for both wet and dry suppression (shaky hoods and dampers). The software automatically decides the best-suited method for the specific job based on operational requirements.