- Home

- Company

- Industries

- Pharmaceutical Industries

- Food and Chemical Industries

- Agro industry

- Cement Industries

- Foundry Industry

- Petrochemical Industry

- Detergent Industry Insights: Sparking Innovation

- Steel & Non-Ferrous Industries

- Distillary & Brewery Industries

- Biscuit and Confectionary

- Fertilizer Industry

- Polymer Industries

- Systems

- Products

- Life At Rajdeep

- Contact Us

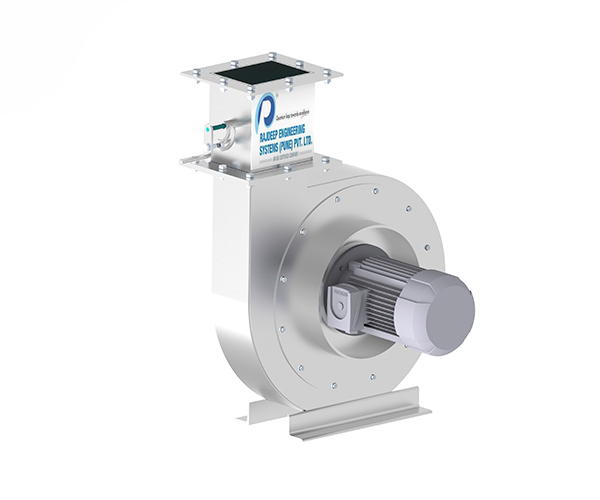

Centrifugal Fans

Centrifugal Fans manufacturers

RAJDEEP manufactures & supplies a wide range of Centrifugal Fans as a product for Industrial Material Handling Systems and ID Fan for Dust Collection Systems. Our product range includes Induced Draft Fans and Forced Draft Fans to meet the specific requirements of the applications. Customers are easily available with a wide range of High-Pressure Centrifugal Fans as per the specifications confirming the international standards at RAJDEEP.

Salient Features:

Centrifugal fans are crafted with either forward or backward-curved blades. Those with forward-curved blades are paired with a scroll housing for quieter operation, while fans with backward-curved blades are designed as freewheeling fans and do not need a scroll housing. A distinctive feature of centrifugal fans with external rotor motors is the placement of the motor within the impeller, which not only ensures optimal motor cooling but also contributes to a more compact design. The full product line includes options with both AC and GreenTech EC technologies, enhancing energy efficiency. These fans are equipped with integrated electronics, enabling a wide range of control, monitoring, and maintenance capabilities suitable for smart home applications and Industry 4.0 environments.

Key benefits of centrifugal fans from Rajdeep include:

– Availability of both AC and EC centrifugal fans with forward-curved blades.

– “RadiCal” AC and EC fans for low-pressure applications, with “RadiCal” EC models available in a scroll housing for a complete system solution.

– “RadiPac” and “RadiFit” EC fans for medium-pressure needs, showcasing the versatility of the product line.

– The compact design is achieved through the use of external rotor motor technology.

– A comprehensive selection of fans suitable for a wide array of applications.

– Full speed control, adjustable via analog or serial interfaces for precise operation.

– High efficiency is realized through the adoption of GreenTech EC technology.

– Quiet operation is ensured by advanced flow control and the sophisticated commutation of EC motors.

– Simplified start-up processes thanks to perfectly matched components: control system, motor, and fan.

– An extensive range of accessories to complement and enhance the fan systems.

BENEFITS OF CENTRIFUGAL FANS:

Centrifugal fans boast several key benefits, such as:

– High Airflow Capabilities: While centrifugal fans excel in moving large amounts of air, they are particularly noted for their ability to handle situations requiring high pressure, unlike axial fans, which are more suited for high-volume, low-pressure tasks.

– Superior Pressure Handling: These fans are adept at navigating through systems with higher resistance, making them suitable for a variety of demanding applications.

– Energy Efficiency: Centrifugal fans showcase notable efficiency. The energy needed to move air grows exponentially with the speed of the air, yet the power needed to operate a centrifugal fan increases at a slower rate, offering energy savings. Delve deeper into this aspect by exploring the three Fan Laws.

– Reduced Noise: Typically, centrifugal fans operate more quietly compared to other types of fans, making them a preferred choice in environments where noise is a concern.

– Versatility: Their design and operation make centrifugal fans a fit for a diverse array of industrial and commercial settings, underscoring their adaptability.

These attributes underscore the versatility and efficiency of centrifugal fans across various applications.

Salient Features:

- High-efficiency robust design

- Impeller with backward curve & backward inclined & radial blades

- Sturdy and heavy-duty construction for reliable vibration-free/long-lasting performance.

- Capacities from 100 m3/hr to 3,00,000 m3 /hr and pressure up to 120m bar

- High fan efficiency and relatively low noise levels

- Blade shape is conducive to material buildup

- Drive arrangements: The electric motor is the power source of the fans. For larger units, the motor is coupled directly to the fan or indirectly by a belt drive, unlike packaged fans

- Performance tested as per relevant IS standards in the factory “performance test rig”

- Available in spark-proof construction.

- VIV dampers for changing airflows without much varying pressure.

- Flow control can be done by inlet dampers.

- MOC: MS/ SS 304 / SS304L / SS316 / SS316L/FRP

Type:

- Induced Draft Fans

- Forced Draft Fans

- Dust extraction fans.

- Pneumatic conveying fans.

- Material Handling Fans.

- Silo venting Fans.

- Ventilation Fans.

- Cooling /Hot Air application fans.

- Dryer ID/FD fans.

- Axial Fans