- Home

- Company

- Industries

- Pharmaceutical Industries

- Food and Chemical Industries

- Agro industry

- Cement Industries

- Foundry Industry

- Petrochemical Industry

- Detergent Industry Insights: Sparking Innovation

- Steel & Non-Ferrous Industries

- Distillary & Brewery Industries

- Biscuit and Confectionary

- Fertilizer Industry

- Polymer Industries

- Systems

- Products

- Life At Rajdeep

- Contact Us

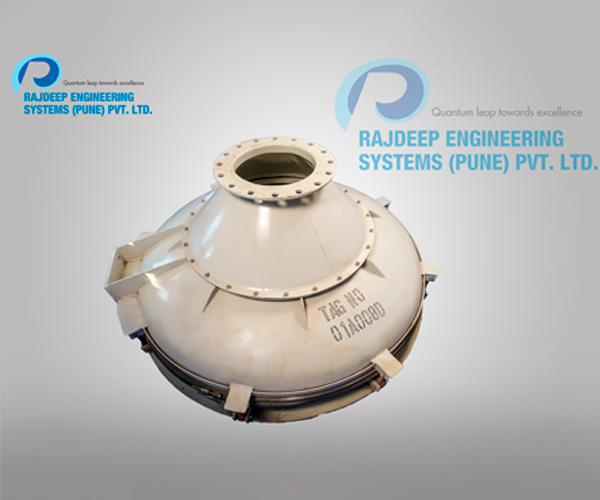

Bin Activators

Bin Activators

RAJDEEP’s Bin activators have already proven their worth the world over as the most effective silo discharge solution even for the most difficult materials.

Rajdeep’s agitator is minutely designed to cater to every single flow-related challenge that is befallen by processes of discharging, viz., bridging, blockage, segregation, and core flow issues. Along with that, the bin activator acts as one of the major parts, it is composed of a tapered conical structure that vibrates for material flow from hopper into the the motion.

Material is taken a course of equivalent residence time with the conveyor belt activated or driven by the pivoting status of the material, on a first-in-first-out basis. A real convenience in the process is the flange provision alongside that engaged in the device to be welded or bolted down in place of the outlet cone assembly. Therefore, a set of special cat links and an engineered polymer shock absorber provide the expression and flex connecting the bin activator.

The Vibratory Motor will be fixed and comes with the feed bin and gets vibrations on it whenever the feed starts the level of material discharge.

The function of the mechanical bin activator consists of rotary motion which is then passing the movement through the material stored in the bin. The end of the process view is portrayed by a smooth flow from the bin activator feeder outlet into the next processing device. The bin rotator guarantees the products not to be left in the hopper, keeping the system from contamination or efficiency problems.

Advantages:

- Rajdeep’s Bin activator provides positive, trouble-free, continuous discharge from storage.

- The operation is silent, needs no attention & consumes little power.

- The Bin activator consists of a specially profiled discharge head with a baffle above and in line with the discharge opening.

- It is hung from a support ring using hangers.

- Bellow-type sealing sleeves on the upper and lower ensure that there is no spillage of material.

- One or two electric vibrators fitted to the unit generate vibration making the material flow normally through the discharge opening of the Bin Activator.

- It can be rapidly installed by bolting/welding to a silo of any shape round or square

- It is a simple, rugged, and reliable & maintenance-free device.

- Sizes Available from 300 to 3600 mm diameter.

- MOC: MS, SS304, SS304 L, SS316, SS316L.

Application industries/area:

- Food Industry: Monitoring the Amount of Flour, Spice, Soy, Sugar, Dairy Products, Herbal Mixtures, and Supplements.

- Forest Products: Making Wood Chips & Sawdust to be Processed.

- Agriculture: The production & distribution of Animal Feed, Fertilizers, Soybean Meal & Spent Grain Learn Vocabulary from the Text:

- Chemical Industry: The Changing Sources: Juices, Pigments, Additives, Starch, Carbon Black.

- Steel Industry: The paradox of artistic decision-making might seem elusive, but it is essential to grasp how various components of an artwork interact to achieve a complete composition.

- Mining Industry: Providing base materials, secondary and operational raw materials that create the kiln itself as well as the fuel and lime.

Applications:

Bin Activator can handle all difficult products like:-

- Soya Flour, All-grain flour

- Whey powder, Milk powder

- Sodium Bicarbonate

- Soda Ash

- Lime

- Talcum Powder

- Gypsum

- Fly ash

Features:

- Available in various types, our products are designed to help keep items out of the bowels of any tanks and compartments.

- Preformed mold and tooling ensure concentricity while the hole is being made, therefore, every hole has the same profile.

- Hangers of suspension give the dish head the maximum level of vibration resistance, and a robust system with these built-in shortcomings well manages both machine and material loads.

- We have engineered our systems to deliver very efficient systems that run with minimal power.

- Each component could also be welded or screwed into place for the ease of assembly.

- Moreover, our laboratory, which is fully functioning, enables finding optimum settings of the whole system, which means that all the outcomes will be better in this case.