Currently manufacturing geography dynamics is fleetly changing, being fast and precise, using robotization, and other new technologies isn’t just a advisability; it’s a necessity to keep ahead of challengers. piecemeal from that list of the graduate technologies which are shaping the product processes the Auto Weighing and Batching are worth to be paid attention to in the first place. These technologies go beyond just transubstantiating running processes of accoutrements , also now defining the new morals for delicacy, product uniformity, and manufacturing excellence.

The Essence of Auto Weighing and Batching:

At the base, the Auto Weighing and Batching is concerned with making the whole process of importing and mixing the raw accoutrements or constituents according to the specified amounts and rates basically automated. The consummation of this robotization gets important in those leading diligence where delicacy is pivotal like medicinals, food and potables, chemistry, where chemical processing diligence, construction accoutrements , and soon.

The Auto Weighing Process:

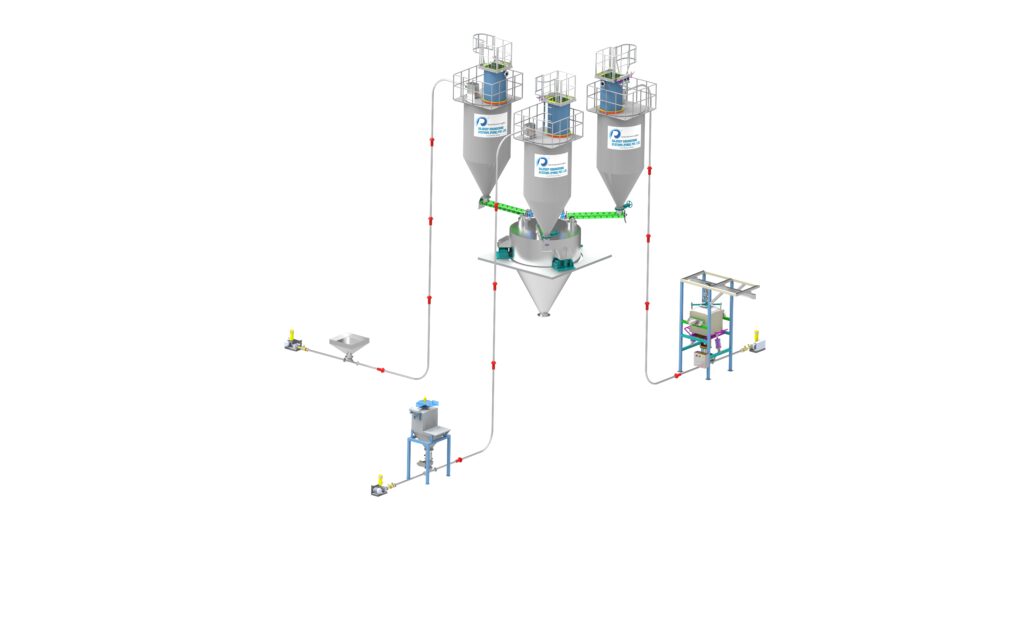

The slice- edge Auto Weighing and Batching technology is grounded on the rearmost detectors and scales that track the weight of accoutrements with extreme perfection. With similar systems, the accoutrements from the fine maquillages to big grains can be handled as needed and the specific quantum that goes into the product process is assured every time. The high tech systems of these processing machines enables the operations to be modified on an moment which in turn ensures the quality of the contents.

The Batching Process:

The necessary mixing is followed by batching, which consists of blending the counted essence according to destined proportions to form a batch. This process can be either homemade or automated but the would only be applicable to the batching systems bones that are automated. These systems offer exceptional advantages that are unexampled in terms of speed, thickness, and reduced man- made crimes. The automatic batching systems insure that all the way regarding the sequence, timing and haste of adding each of the element, are reused unevenly, so the end of each blend fulfils all the requested specifications.

Benefits of Auto Weighing and Batching:

- Enhanced Delicacy and Thickness: The capability of Auto Weighing and Batching to maintain the high delicacy and thickness among the batches comes out an essential advantage of this class of systems. This delicacy is vital in assuring the products’ quality, efficacity, and safety centers like medicinals or food product diligence, and especially, they should surely.

- Increased Effectiveness and Productivity: The primer importing and the batches can be reduced presto and on demand with automated importing and batching, therefore largely saving time and mortal coffers. This turn in effectiveness traces out to advanced productivity, which allow for redundant batches to be produced in a shorter time without a concession in quality.

- Reduced Waste and Cost Savings: Minimizing product and Transportation Waste and as a Result of this the Costs will be Saved Stated in another way, we hold accurate measuring and mixing in high regard to both quality and waste plutocrat forestallment. Through precisely measured constituents, companies can realize low cost product and contribute not only to further sustainable practices but also to further environmentally friendly product.

- Advanced Worker Safety: Robotization cutting off chances of dangerous chemicals poisonous substances to get to the worker reduces exposure threat. motors importing and batching systems designed to operate in an terrain with limited openings or release of product to the ambient atmosphere can reduce the probability of failure due to mortal error and ameliorate safety of workers.

Implementation Challenges:

Although Auto Weighing and Batching can reduce error, precise installation and configuration of the systems with the targeted manufacturing process are still tough to realize. similar costs number massive investment in structure, adaptation of the tools with the current product lines, and training of the staff drivers and maintainers. still, the hump of ROI juxtaposed with these challenges may be unexpectedly easy justifying through enhancement of effectiveness, junking of waste, and improvement of product quality.

The Future of Auto Weighing and Batching

The prospects of the bus importing programming and batching look to be promising and developments in detector technology, data analytics, and machine literacy are all continuing. These technologies will go indeed better allowing for delicacy, duration, and versatility advancements in the Auto Weighing and Batching system. similar as, preventative conservation can help optimize the moment, performing in applicable time-out and dragging the life of the outfit. In addition, the capacity to acclimate fashions using real time data and produce products that meet the guests ’ preferences and request demands within the optimal conditions is doable among AI and machine literacy technologies.

Integration with Industry 4.0

Along with the rapid-fire metamorphosis of perpendicular integration known as Assiduity4.0, Auto Weighing and Batching systems develop as a part of interoperable product processes. This connection provides a much further approach which is holistic in nature to the manufacturing process, because also, the data from several stages can help in the decision making process to make the manufacturing be smarter, briskly, and responsive at the same time.

The IC Auto Weighing and Batching systems are a considerable shift that nearly all manufacturing areas in numerous diligence are serving from. These technologies not only they helps to increase the delicacy, speed, and safety of the product process but also they give substantial cost savings and environmental benefits. Manufacturing conventional processes are likely to be farther amended by defense technologies progressing in detector technology, data analytics, and machine literacy. These manufacturer people should be in time when aiming for changes and updates in the global request which is fast and dynamic.