In today’s fast world, moving materials quickly is key for better production and profits. The lean phase conveying system is a new tech changing how we handle materials. It brings many benefits, like better work flow, lower costs, and safer, greener operations.

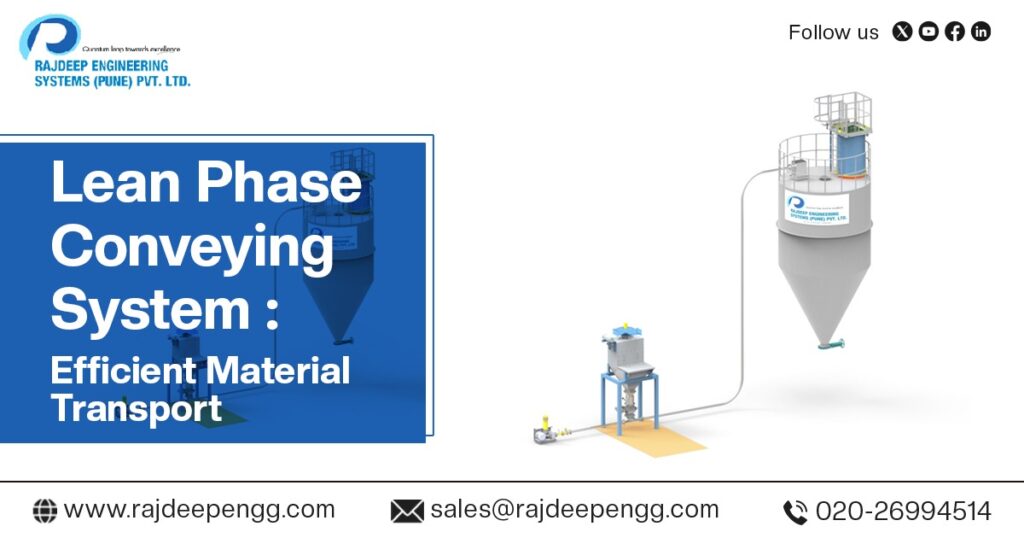

At the core of these systems is a simple idea: moving materials smoothly in a closed loop. They use advanced air tech to move many types of materials, like powders and fragile items, with great accuracy and dependability.

This article will dive into the details of lean phase conveying systems. We’ll look at how they work, their parts, and their uses in different fields. Whether you work in making things, moving goods, or just want to know about new material handling tech, this guide will help you understand how these systems can change your work for the better.

Key Takeaways:

- Lean phase conveying systems offer efficient and reliable material transport solutions for various industries.

- These systems leverage advanced pneumatic technology to ensure seamless and controlled movement of materials, improving productivity and reducing operational costs.

- Key components of a lean phase conveying system include air movers, blowers, conveying lines, and bends, all designed to work in harmony for optimal performance.

- Lean phase conveying systems can be applied across diverse industries, from manufacturing and food processing to pharmaceutical and chemical industries.

- Careful system design and maintenance are crucial for maximizing the efficiency and longevity of lean-phase conveying systems.

What is a Lean Phase Conveying System?

A lean phase conveying system is a modern way to move materials. It uses air flow to transport materials through pipes or ducts. This method is more efficient than old mechanical ways.

It saves energy, improves product quality, and keeps workers safe. This system is key for better industrial conveying.

Understanding the Principles of Lean Phase Conveying

This system moves materials with air pressure, not big machines. It can handle many types of materials, from powders to big chunks. This makes the material handling process smoother.

It also makes production more efficient by using less energy. This helps save money and is better for the environment.

Benefits of Using a Lean Phase Conveying System

- Improved energy efficiency, leading to cost savings and reduced environmental impact

- Enhanced product quality due to gentler handling and reduced material degradation

- Increased safety for workers by eliminating the need for physical interaction with conveyors

- Versatility in handling a wide range of materials, from fine powders to larger particles

- Reduced maintenance requirements compared to traditional mechanical conveying systems

“Lean phase conveying systems are revolutionizing the way industries approach material handling, offering a more efficient and sustainable solution that optimizes production processes.”

How Does a Lean Phase Conveying System Work?

A lean phase conveying system is a top choice for moving materials in industries. It’s efficient and easy to understand, making it popular in manufacturing and processing.

The system uses an air mover and blower to push and pull materials. These parts create the air pressure needed to move materials through pipes or ducts. Materials like powders, granules, pellets, and small objects are moved using this airflow.

The system’s efficiency comes from its design. The way the conveying lines and bends are set up helps materials flow smoothly. This method is different from old ways because it doesn’t need complex parts. This means less maintenance and lower costs.

“The lean phase conveying system’s unique blend of air pressure and gravity-driven transport allows for a highly efficient and streamlined industrial material handling process.”

Lean phase systems use air pressure and gravity to move materials. This makes them versatile and adaptable for many industrial material handling needs. It’s a new way to transport materials that are becoming more common in industries looking to improve their processes.

Components of a Lean Phase Conveying System

A lean phase conveying system has key parts like the air mover and blower. It also includes the conveying lines and bends. These parts work together to move materials smoothly in industrial places.

Air Mover and Blower

The air mover and blower are vital in a lean-phase system. They create the air pressure and airflow needed to move materials. The air mover makes the pressure, and the blower controls the airflow. This helps the lean phase conveying components move efficiently.

Conveying Lines and Bends

The conveying lines and bends are the paths for materials to follow. They guide the air mover, blower, and materials. This ensures a smooth flow. The design of these lines and bends is key to the system’s efficiency.

“Lean phase conveying systems are designed to minimize waste and maximize productivity, with the air mover, blower, conveying lines, and bends working together to achieve this goal.”

Knowing the importance of these components helps businesses improve their material handling. They can design a lean phase system that boosts efficiency and productivity.

Applications of Lean Phase Conveying System

Lean phase conveying systems are used in many industries. They are great for moving fine or powdery materials. This makes them a good choice for many material transport needs.

In food processing, these systems are perfect for moving ingredients like flour and sugar. They keep the ingredients flowing smoothly and maintain their quality. This is important for making food products.

The pharmaceutical manufacturing field also uses lean phase conveying. It’s great for moving delicate materials without contamination. This is key for making safe and high-quality medicines.

In chemical production, these systems are good for moving chemicals like pigments. They help avoid dust and spills, keeping the area clean and safe. This meets important safety and environmental rules.

The mining industry also benefits from lean phase conveying. It’s good for moving ore and coal without dust. This makes material transport safer and more efficient in mines.

| Industry | Lean Phase Conveying Applications |

|---|---|

| Food Processing | Flour, sugar, spices, and other food-grade powders |

| Pharmaceutical Manufacturing | Active pharmaceutical ingredients (APIs), excipients, and other delicate materials |

| Chemical Production | Powdered or granular chemicals, such as pigments, catalysts, and specialty chemicals |

| Mining Industry | Ore, coal, and other mined materials |

Lean phase conveying systems are used in many industries. They make material transport reliable, efficient, and cost-effective. This helps improve production and makes operations more efficient.

Lean Phase Conveying System vs. Other Material Handling Methods

The lean phase conveying system is a top choice for moving materials efficiently. It beats traditional systems in many ways. It’s more cost-effective and uses less energy.

Advantages Over Traditional Conveying Systems

This system uses less energy than others. It works with air to move materials, saving a lot of power. This means big savings for businesses and less harm to the environment.

It also keeps materials in better shape. Unlike old methods, it doesn’t damage or mix up products. This leads to better quality and less waste.

It’s safer for workers too. The system is closed and automated. This cuts down on risks and makes the workplace safer.

Its design is another big plus. It’s small and can fit into tight spaces. This makes it easy to add to existing setups, improving space use and flexibility.

“The lean phase conveying system is a game-changer in the world of material handling, offering unparalleled efficiency, safety, and flexibility.”

Using lean phase conveying can make businesses more efficient. It cuts costs and improves product quality. This makes production more competitive and sustainable.

Designing an Efficient Lean Phase Conveying System

Creating a lean phase conveying system requires careful planning. Many factors must be considered to improve how materials move and how well the system works. Engineers must study the materials and the factory’s layout closely.

Key Factors in System Design

To make sure the system works well, designers must focus on a few key things:

- Air Velocity: The right air speed is key for smooth material flow.

- Pipe Diameter: The pipe size must fit the material volume and type.

- System Pressure: The right pressure can cut energy use and boost efficiency.

By balancing these elements, engineers can build a lean phase conveying system design. This design will offer better system optimization and material handling.

“The key to an efficient lean phase conveying system lies in the meticulous consideration of material properties, facility layout, and industry-specific requirements.”

The success of a lean phase system depends on the designer’s detailed analysis. They must combine material handling design factors into a single, effective solution.

Lean Phase Conveying System: Maximizing Efficiency

Lean phase conveying systems help businesses improve their material handling. They lead to better productivity improvements and operational cost savings. These systems use less energy, reduce damage to products, and boost overall efficiency.

These systems control material flow well, ensuring smooth transport. This control means less waste and better adaptability to production changes. It’s all about lean phase conveying efficiency.

Lean phase systems also protect products from damage. This keeps materials in good condition, improving product quality. It also saves money by reducing the need for replacements or rework.

To get the most out of these systems, it’s important to tailor the design. This might include optimizing air movers and blower setups. It also means placing lines and bends wisely and using advanced monitoring and control systems.

“Lean phase conveying systems have the potential to revolutionize material handling, delivering unparalleled efficiency and cost savings for businesses of all sizes.”

Investing in a well-designed lean phase conveying system can bring big benefits. Companies can see major productivity improvements and operational cost savings. This sets them up for success in a competitive market.

Maintenance and Troubleshooting Tips

Keeping a lean phase conveying system in top shape is key. Regular upkeep and quick fixes help avoid downtime. This keeps your lean phase conveying system running smoothly.

Common Issues and Solutions

Problems like blocked pipes, worn parts, and air pressure issues can pop up. Here’s how to tackle them:

- Check the pipes and bends for blockages and clean them when needed to keep airflow right.

- Watch the air mover and blower for wear and replace parts to keep air pressure steady.

- Keep the electrical and control parts, like sensors and valves, in good shape to avoid performance problems.

Fixing lean phase conveying system problems early on helps avoid downtime. It keeps your system running at its best.

| Common Issue | Potential Cause | Solution |

|---|---|---|

| Blocked pipes | Buildup of material or debris | Inspect and clean the conveying lines regularly |

| Wear and tear on components | Prolonged use or excessive stress | Replace worn or damaged parts as needed |

| Fluctuations in air pressure | Issues with the air mover or blower | Maintain the air mover and blower components |

By tackling these common issues and sticking to a lean phase conveying system maintenance plan, you can make sure your system works well for a long time.

Conclusion

The lean phase conveying system is changing the game in material handling. It brings many benefits to modern industrial operations. These systems use pneumatic conveying to improve energy efficiency, product quality, and worker safety.

These systems are versatile and fit into many industries. They are used in food processing, pharmaceuticals, mining, and chemical processing. As companies look for ways to be more productive and cost-effective, these systems are becoming more popular.

In summary, lean phase conveying systems offer many advantages. They improve material handling and boost industrial productivity. By understanding these systems, businesses can make their material transport better. This can help them stay competitive and achieve success.