- Home

- Company

- Industries

- Pharmaceutical Industries

- Food and Chemical Industries

- Agro industry

- Cement Industries

- Foundry Industry

- Petrochemical Industry

- Detergent Industry Insights: Sparking Innovation

- Steel & Non-Ferrous Industries

- Distillary & Brewery Industries

- Biscuit and Confectionary

- Fertilizer Industry

- Polymer Industries

- Systems

- Products

- Life At Rajdeep

- Contact Us

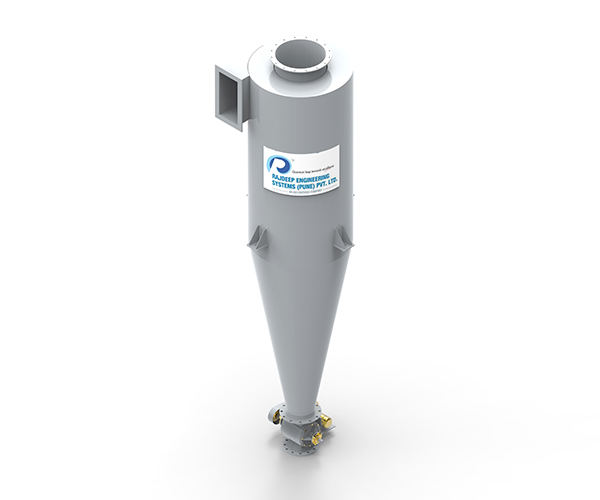

Cyclone Separators

Cyclone separators manufacturers

Cyclone separators are used for cyclonic action to separate dust particles from the gas stream. In a typical cyclone, the dust gas stream enters at an angle and is spun rapidly. The centrifugal force created by the circular flow throws the dust particles toward the wall of the cyclone. After striking the wall, these particles fall into a hopper located underneath. Cyclone separators create a dual vortex to separate coarse from fine dust. The main vortex spirals downward and carries most of the coarser dust particles. The inner vortex created near the bottom of the cyclone spirals upward and carries finer dust particles.

Cyclone dust separators are available in various configurations to cater to diverse application needs. Here are some common types:

- Inertial or Gravity Cyclones: These are the most prevalent cyclone types, and utilize a combination of rotational forces and gravity to separate dust and particles from the air stream. As air spirals within the cyclone, heavier particles are propelled towards the walls and settle at the bottom.

- High-Efficiency Cyclones (HECs): HECs are engineered to extract smaller particles from air streams compared to gravity cyclones. They typically feature a taller build and smaller diameter, creating an extended path for particle separation.

- Multiple Cyclones: This setup comprises a cluster of cyclone separators arranged in series or parallel. They find application in scenarios requiring the removal of large particulate volumes or the separation of different particle types.

- Twin Cyclones: Twin cyclones consist of two cyclone separators placed side by side. They’re employed to enhance processing capacity or simultaneously handle various particle sizes or types.

- Triple Cyclones: Incorporating three cyclone separators, this setup can be arranged in series or parallel based on the application requirements. Triple cyclones are particularly beneficial in high-volume situations with diverse particulates.

- Quadruple Cyclones: As the name suggests, quadruple cyclones feature four cyclone separators. These systems offer versatility, enabling simultaneous separation of multiple particle sizes and types.

- Reverse-Flow Cyclones: These cyclones feature a distinct design where inlet air enters from the top, and the dust-laden gas follows a downward spiral path. Dust particles are discharged at the bottom, while clean air exits from the top.

It’s essential to select the appropriate cyclone type based on specific application requirements, including particle size and type, air stream volume, and environmental or operational conditions.

Advantages of Cyclone Separator:

- Simple construction

- Have no moving parts

- Can be used as pre-cleaners to remove coarse particulates and reduce the load on more efficient dust collectors

- Can be designed to remove a specific size range of particles

- Constant pressure drop

- MOC: MS, SS304, SS304 L, SS316, SS316L.

Applications:

- Fertilizer

- Cement

- Paint & Pigment Handling

- Mineral Processing

- Chemicals

- Petrochemicals

- Pharmaceutical

- Distillery / Brewery

- Food Industry

Features:

Cyclone separators are strongly in favor as industry employees consider their affordability, safety, environmental friendliness, and effectiveness among other advantages. Here are some noteworthy characteristics:

- Effective Particle Removal: Cyclones class one of the air supreme ruling particles from the air which effectively makes the industrial sites air in perfect condition.

- Superior Dust Collection Efficiency: Providing an advanced dust collection capacity they ensure up to 95% of airborne particulate matter elimination.

- No Filter Requirement: Unlike other dust collection systems, cyclones are filter-free( have no motor or ducts.) Therefore, maintenance and replacement costs are extremely low.

- Simple and Reliable Operation: The simplicity and the lack of moving mechanisms make the turbines very efficient and reliable; they face few interruptions or breakdowns during their service.

- Long-lasting Durability: Developed based on the robustness concept, cyclone separators are crafted to operate in the most severe conditions thus guaranteeing extended operational periods.

- Energy Efficiency: Cyclone operators are always better energy efficient (fuel) consumers than their counterparts in other air pollution control equipment and as a result, they often yield massive savings on cost.

- Adaptability to Harsh Conditions: These separators can match contaminated air conditions with high temperature and pressure, thus widening their use case to various industrial applications.

- Compact Design: The plea with compact size results in simple assimilation into overall operations, which is appreciable in scenarios where space is restricted.