Manufacturer & Supplier

Leading Powder Handling Systems Manufacturer

What stands out for the powder handling system is the fact that all this diligence are suitable to manage their accoutrements efficiently. From cradle A to Z, manufacturing and processing bear this high component that’s essential for controlling the safety, allocating, and dosing of maquillages. Then, in this comprehensive disquisition, we explore and recite about Powder handling System in detail diving into their functionalities, operations that they serve, and the significance of it that enable the effective application of artificial conditioning.

What is a Powder Handling System?

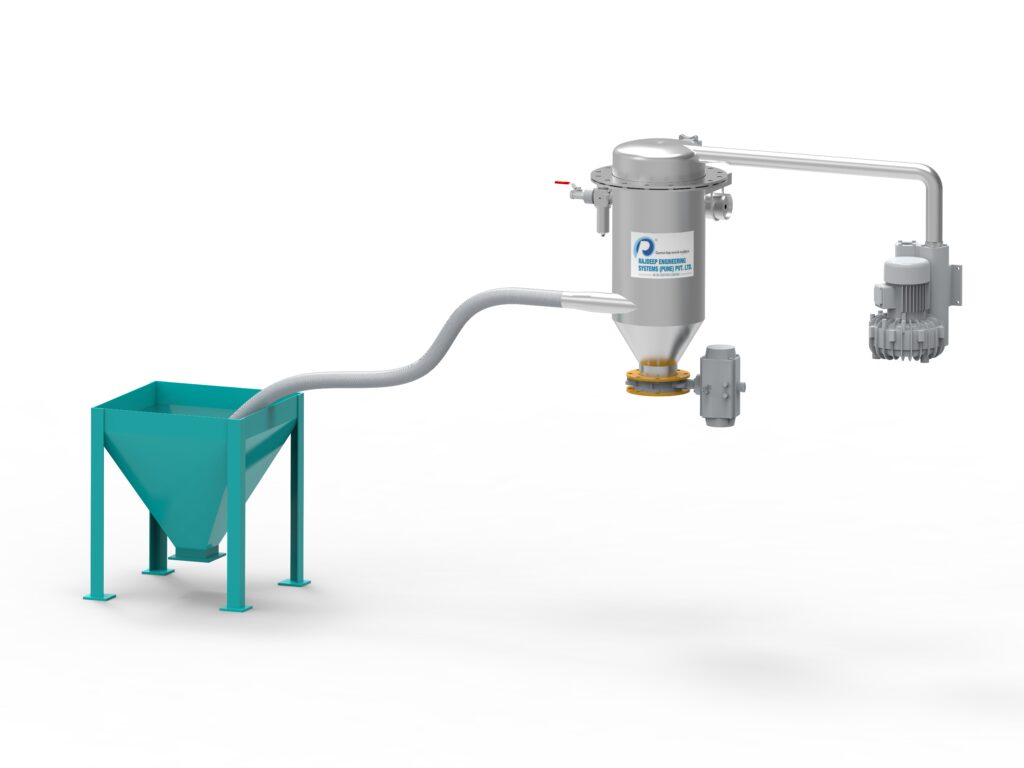

A Powder Handling System is a sophisticated and complex system proposed for running maquillages at different stages of product, including mixing, blending, coating, spray drying, or quilting. These systems are designed to see that the safe transfer, storing, or processing of maquillages occurs, and therefore break the issues of constraint, either on hygiene or perfection. Powder processing Systems are companies come in a variety of configurations that can be designed to match particular diligence primarily.

Applications of Powder Handling System:

- Pharmaceutical Manufacturing: In the pharmaceutical industry, use powder transfer system. They precisely measures and transports different factors, a vital part of medicine products.

- Food Production: For food firms, powder handling systems are especially crucial. They help in mixing and distributing constituents like flour, sugar, and spices. These systems contribute to products including reused foods, ignited foods, baby food, and more.

- Chemical Processing: Amongst chemical manufacturing systems outfit, Powder Handling Systems are the major element responsible for the controlled running and mixing of chemical maquillages with high delicacy and safety.

- Cosmetics Production: In the cosmetics assiduity, where perfection and delicacy are of great significance, Powder system Systems play an important part, in that they deal with the precise running of colors, talc, and maquillages of all kinds to grease the colorful beauty and skincare phrasings.

- Metal Powder Handling system: That diligence involves metalworking or greasepaint metallurgy in comprised of Powder Handling processing Systems where they use essence maquillages for cumulative manufacturing needs through accurate allocating and transport.

- Ceramics Production: Automated and controlled powder handling systems are used for largely accurate measuring and mixing of ceramic maquillages for manufacturing of wall penstocks, crockery, and other ceramic products.

- Agricultural Chemicals: The manufacturing of diseases and fungicides also involves Powder handling Systems processing that allow the effective running and blending of pulverized agrarian substances.

- Battery Manufacturing: Battery Powder Handling Systems are essential for all the batteries being manufactured, for the most accurate running of grease paint which involves electrode accoutrements too as the wrong running of these maquillages can beget low battery performance.

- Construction Materials: In the diligence involved in the manufacturing of construction accouterments, like cement and concrete, the Powder Transfer Systems are used for granulating factors of the grease paint accouterments.

- Powder Coating: Safety and comfort, in manufacturing and post-treatment of the grease paint coating on shells, are the corridor played by the Powder handling Systems in the timber of an invariant cover.

Functionalities of Powder Handling System:

- Material Conveyance: Powder handling systems have conveyors installed on them that enable them to carry maquillages from one area to another anyhow whether it lies astronomically within the installation or between colorful processing ways.

- Metering and Dispensing: Similar metering and mode of allocating systems allow for an exact volume dimension, therefore making it possible to use different product situations.

- Blending and Mixing: Powder handling Systems fulfilled tasks like the controlled blending and mixing of colorful maquillages to gain a homogenous product end-up.

- Containment: The Powder Handling Systems constraint aspects, which are at an advanced position, are in place to avoid pollution of the terrain by the discharge of maquillages and a clean and safe work area are two of the points.

- Cleaning and De-Dusting: The cleaning and dusting procedure, also known as the cleaning and dusting mechanisms, is the reason for the integrity of the manufacturing terrain within Powder handling Systems which, in turn, has a huge impact on the reduction of the impurity threat in this procedure.

- Automation and Control: currently Powder Handling systems are constantly handed with intelligent control and robotization systems, permitting the conservation of the whole process under complete control and taking a minimum intervention of the driver.

Key Components of Powder Handling System:

Powder handling systems must be adequately understood by the functionality principles of the different factors that contribute to their effectiveness.

- Powder Conveyors: These conveyors are erected to transport overcrowded substantial maquillages ineffective and portable accouterments handling systems.

- Powder Hoppers: AEs( Selectors for Snares) or CVTs( Containers or Vessels for Powdered Accoutrements) that keep the Greasepaint before they’re transported or reused.

- Metering Devices: Apparatus needed for precisely allocating and measuring maquillages in variable quantities in the manner of product confirmation.

- Mixers and Blenders: These rudiments enable the coalescence and shifting of the maquillages for the attainment of a well-amalgamated or duly mixed commodity.

- Dust Collection Systems: these are outfits that are veritably inescapably to have a healthy working place, as they capture and remove the airborne dust patches from the terrain of work.

- Valves and Gates: Automated faucets and gates that regulate the inflow of maquillages grease the vehicle of the colorful factors and allow for controlled movement in their paths.

- Filtration Systems: Pollutants that are designed to be suitable to remove contaminations from maquillages as the finishing stage thereby enabling the batch to have high- quality and chastity.

- Control System: Due to important sophisticated control systems control and supervision, full Greasepaint running is regulated and examiner, thus its effectiveness is increased while the number of crimes is minimized.

- Cleaning Devices: Then, we installed the installations to clean the outfit and ranged the way to keep the different maquillages from cross-contaminating each other.

- Safety Features: The exigency stop bias, admonitions, and safety interlocks are universal outfits used across the dust operation system that provides safety for the entire system and its drivers.

Explaining the tasks these corridors carry out gives sapience into the consonance of the complete Powder Handling System functional process.

Challenges and results in Powder Handling System:

1. Material isolation In comparison to the other sectors, the powder handling systems must deal with the isolation of accoutrements , similar that all the powdered patches achieve the livery composition.

2. Dust Emission The issue of dust flyspeck emigrations when dealing with greasepaint operations is always a problematic area that should be handled in a well-designed dust birth system considering filtering conditions.

Powder Handling System: Challenges and Solutions

1. Material Separation: A Powder handling system must be suitable to retain the material separation it requires to maintain uniformity in its products.

2. Dust Pollution: Containing dust patches can be a demanding task in Powder handling egging for effective dust control and sanctification systems.

3. Moisture Sensitivity: Specialized handling systems incorporating humidity control features are needed for maquillages that are largely sensitive to humidity.

4. Cross-Contamination For diligence dealing with multiple maquillages, there’s always the threat of cross-contamination, therefore challenging elaborate cleaning mechanisms between different processing runs.

5. Cleanliness Regulations and Norms Powder Handling Systems must be designed considering strict norms of hygiene and nonsupervisory compliance typical in fields similar to medicine and food processing.

6. Flowability Problems Some maquillages may have flowability problems hence objectification of either vibration or aeration becomes necessary to enhance their inflow.

Advancements in Powder Handling Technology:

- Internet of Effects ( IoT) Integration Numerous contemporary Powder handling systems include Internet of Effects technology which makes real-time monitoring, data collection, and remote control possible among others.

- Automated Cleaning Systems: Powder Handling Systems are more productive since they reduce functional time through advanced automated cleaning systems rather than homemade cleaning.

- Material Tracking Systems: The use of technologies similar to RFID and barcode allows for accurate shadowing of greasepaint accouterments during running stages.

- Smart Detectors: The delicacy in measuring and allocating grease paint is bettered by the objectification of smart detectors, therefore enhancing system-wide perfection.

- Predictive Maintenance: By employing prophetic conservation algorithms, a Powder handling System can prognosticate implicit issues and plan conservation to reduce time-out.

The Powder Handling System is a fundamental component of modern artificial accessory management. It finds operations in Pharmaceuticals, food processing, and chemicals among others; multitudinous features contribute towards its functionality and effectiveness as a result this system plays a pivotal part in securing by containing maquillages within strict limits. This also means that it’ll be possible for robotization technology to drive the unborn advancement of this system into the bone that integrates the Internet of Effects ( IoT) and smart seeing leading to better artificial operations performing in meeting ever-changing conditions from different diligence where these systems find use.