Powder Transfer System

A powder transfer system is a device designed by manufacturers to elevate powdered accessories so they may be moved from one location to another. Such a system is grounded on the curvaceous conveying principle which involves the suspense of mineral mass in the air using air pressure or vacuum.

In the fields of drugstore, food processing, chemicals and cosmetics maquillages are transported snappily and safely in the same manner without any chance of impurity or spillage using the Powder handling systems. In this short composition, we shall unravel the relational underpinnings of Powder handling systems and will cover the following points functionality, types, operations, and benefits.

Understanding the Basics of powder Transfer Systems

The substance of a powder transfer system understanding can be deduced from the functional process, rudiments involved in the system’s functioning and the principles of conveying material through curvaceous conveying. This section will, first of all, dissect the numerous abecedarian principles of powder conveying systems in a detailed manner.

Types of Powder Transfer Systems Pressure and Vacuum Conveying

There are two main types of powder handling systems plural impact( pressure gauging and vacuum conveying) In case of distinguishing different types, they all have individual traits, pros, and cons. We will dig into the colorful areas that make up pressure and vacuum conveying mechanisms.

Factors of a Powder Transfer System Pollutants, boasters, and Receivers.

The system for the transfer of the powdering is typically divided into two branches; one is responsible for the several kinds, each with unique qualities, positive aspects, and drawbacks. It’s a combination of both the pollutants that are used to remove contaminations in addition to the suckers, boasters and soporifics for the exchange. This member will allow to uncover the part of each component for case, screw conveyor, auger, or rotary stopcock and how these constituents perform during powder transferring.

Operations of Powder Transfer Systems in the Pharmaceutical Industry

When a powder transfer system is employed for blending, agglomeration and tablet contraction, it becomes one of the significant factors in the pharmaceutical member of the assiduity. In this section, the pupil will explain about the oneness of their Powder handling systems in the environment of the medicinal manufacturing process.

Benefits of Powder Transfer Systems Efficiency and Waste Control

The manuals of the greasepaint hoppers filled with a curvaceous conveying system or a mechanical conveying system, to transfer material from one position to another have several advantages in the assiduity that include enhanced material handling system, smaller impurities and bettered health of the workers. The posterior area will suggest ways powder transfer styles can be helpful to industry.

Challenges and Considerations in enforcing Powder Transfer Systems

Agitating difficulties and Features for the Installation of Powder Transfer Systems Although powder transfer systems give multitudinous advantages, maintaining the system comes with conditions; system armature should be considered and functional difficulties. The coming part focuses on the issues and factors to examine when introducing to powder handling systems.

Conservation and drawing Procedures for Powder Transfer Systems

Timely conservation and cleaning of these systems enable them to serve as a whole and gives them the capacity to repel clogs and impurity problems. Then we will explain the service procedures for the Powder handling systems and show drawing morals.

Cost Analysis of Powder Transfer Systems original Investmentvs. Long- Term Savings

Conducting a cost analysis for the powder conveying systems of the business provides necessary birth information about the outspoken investment demanded as compared to the benefits and savings the association may dodge in the long run. In this part, we go into detail from the fiscal issues related to powder transfer systems similar as accession costs, conservation freights and it also takes into consideration the functional savings.

Environmental Impact of powder Transfer Systems

Besides the added functional benefits, powder transfer systems also have an obviously favorable environmental impact wherein they reduce dust emigration and enhance air quality in the artificial installations. This will help to look into the green attributes of paddle bus.

Future Trends in Powder Transfer Systems robotization and Digital Integration

As diligence that are now shifting to robotization and digital recording, powder transport systems previsioned for relinquishment of newest technology and developments. Hence, this section will show the trends in powder transfer for the future applying robotization, remote monitoring, and prophetic conservation.

Powder transfer systems are fine outfit that are sine qua non in effective operations and secure operation of maquillages in different sectors. The correct way to know about the mechanics, types, uses, and benefits is through the perpetration of the powder handling systems for the businesses that are willing to ameliorate the process of material running and gain functional effectiveness.

Key Product Features:

- Seamless installation on existing reactor/blender/silo setups

- Compact and modular design for versatile deployment

- Reliable and clean material handling method

- Capability to charge various vessels effortlessly

- Utilization of TC end connection for enhanced performance

- Guarantee of contamination-free material handling

- The dust-free operation ensures a clean working environment

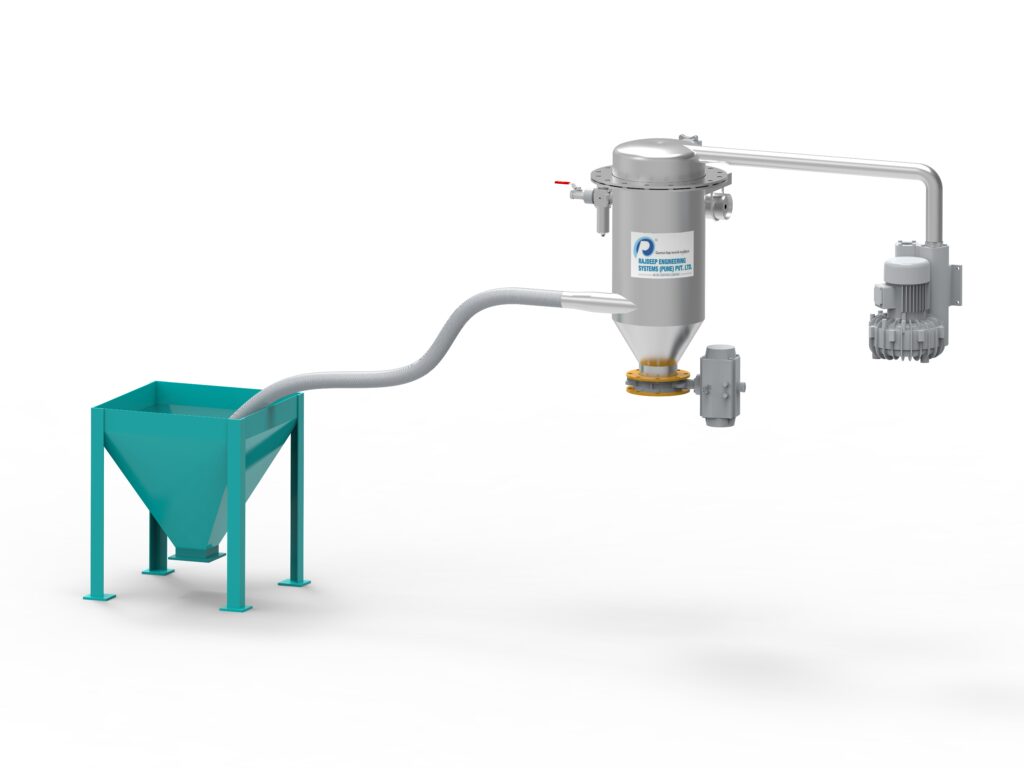

Components Used in Powder Transfer System

Powder feed hopper / Powder suction tool

PTS vessel with automated valves & regeneration-type filter

Vacuum pump / Control Panel

Intermediate piping & fittings