- Home

- Company

- Industries

- Pharmaceutical Industries

- Food and Chemical Industries

- Agro industry

- Cement Industries

- Foundry Industry

- Petrochemical Industry

- Detergent Industry Insights: Sparking Innovation

- Steel & Non-Ferrous Industries

- Distillary & Brewery Industries

- Biscuit and Confectionary

- Fertilizer Industry

- Polymer Industries

- Systems

- Products

- Life At Rajdeep

- Contact Us

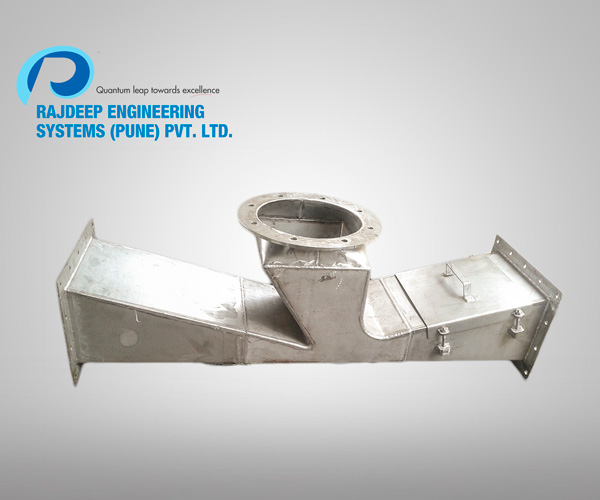

Venturi Eductor

Venturi Eductor

RAJDEEP provides Venturi Eductor for conveying materials.

The venturi eductor reduces the pipeline cross-sectional area in the region where the material is fed from the supply hopper. There are no moving parts in this feeding device which has certain advantages with regard to wear problems.

The effect of the reduction in flow area is an increase in the entraining air velocity & corresponding decrease in the pressure in the region

These feeders are usually incorporated in systems that are required to convey free-flowing materials at low flow rates.

Rajdeep’s venturi feeder, a dynamic yet static device devoid of moving parts, efficiently injects solids into a high-pressure gas stream for advanced pneumatic conveying. The venturi-based pneumatic conveying system excels in transporting a diverse array of bulk solids, leveraging the precise entrainment of solids and secondary gas that the venturi eductor and subsequent machinery are equipped to manage, thus establishing a self-adjusting mechanism. Central to this system, the venturi nozzle, when integrated with a high-pressure blower, becomes the fundamental driving force behind the material conveying system. The eductor facilitates the continuous movement of materials, maintaining a moving-part-free airflow in the conveying process and ensuring the system remains maintenance-free.

Designed with dust-free operation in mind, this pneumatic conveying system employs venturi eductors for the transport of materials that are abrasive, fine, fragile, or irregularly shaped. Its application is particularly effective in handling large volumes of bulk powder, pellets, and granular materials.

Rajdeep’s engineering team is committed to providing a tailored venturi-based pneumatic conveying system that meets your specific needs, offering expertise and customization to enhance your operational efficiency.

WHAT ARE VENTURI EDUCTORS AND WHAT DO THEY DO?

An air educator is one of the essential parts of an air transport conveyor. It enables the transport of powders, pellets, and bulk granular in fixed distances, over considerable heights. Using the machine Venturi principle the educators efficiently diabolize low-pressure air with a high-pressure air stream and as a result, it becomes intermediate pressure with the fluid flow through its whole length. With their ability to pneumatically convey up to 15 tonnes per hour over lengths of 100 meters, Venturi mixes offer an attractive option for conveying. As they possess no moving parts, they function with minimal maintenance and go on serving for long periods of their life consequently ensuring flawless performance.

HOW DO THEY WORK

The pressure part of the air which again will be accelerated is the push (the motive) and after it changes into velocity. The moving of the corn through the eductor creates a vacuum that enables the centrifugal force to move the shells away from the corn. This endows the air with low pressure which on its part results in a vacuum effect that is due to the suction The two air masses and the product are drawn in and then follow the squeezing process which is the re-pressurisation of the eductor to the middle pressure. The mixture of steam and water then starts to be pushed back in the opposite directions until the original velocity gets turned into pressure and the product at last comes out from the outlet.

Venturi Eductor mainly comprises of:

- Eductor Body

- Nozzle

- Diffuser

Salient Features of Venturi Eductor:

- Conveying Solids with No Moving Parts.

- Small, occupy less space & cheaper

- No Maintenance

- No Blow-Back

- Minimum Product Degradation

Venturi Eductors are used to feed bulk solids such as powders, powdered spices, pellets, flakes, rubber crumb, Styrene Butadiene Rubber, and particulates having low bulk density, into Lean phase conveying systems of Pneumatic Conveying Systems.

Product Features:

Adjustable nozzle positioning enables optimal performance customization.

Ideal for high-temperature solids and abrasive materials.

No valves, dampers, or choppers in conveying line, minimizing maintenance needs.

Constructed from painted carbon steel or stainless steel.

Keeps blower separate from conveying stream.

Venturi technology utilizes positive and negative pressure.

Ensures no smearing, shearing, or degradation of handled solids.

Simple system restart, even with injector and conveying line full of solids.

Ensures continuous operation.

Superb for trim handling applications.

Specifications:

Specifications for Vacuum Type Venturi-Based System

– Conveying Rate: Low, typically ranging from 1 to 4 tons/hr

– Conveying Velocity: 20 m/s to 25 m/s

– Conveying Distance: Up to 15 to 25 meters

– Air Mover: FD Fan / Tri-lobe / Ring channel blower

– Operating Pressure: Up to 100 mbar(g)

– Solids Loading Ratio: 1 to 5