Vacuum Conveying is one of the most valued systems in the ultramodern world when you’re talking of the advanced accoutrements handling systems that are precise and effective. It’s this operationally elite technology that’s used in curvaceous vacuum vehicle whereby the manner in which diligence handle different accoutrements is fully changed. The present composition specifically explores the commencement and working of Vacuum running, pressing its serviceability, benefits and crucial outfit. Take part in the passage through which the main principles of Vacuum handling get exposed to the focus together with their central position in contemporary artificial processes.

What is Vacuum Conveying?

Right at the basics, the Vacuum Conveying process is a medium of transport for accoutrements that operates by means of a vacuum for moving the patches through a channel. Such an advanced system works grounded on discrimination pressure which is applied to the area around the mouth of the tube, bringing accoutrements straight to the other point of birth. In discrepancy with the conventional conveyors, a Vacuum Conveying involves minimization of the chance of damage on the core accoutrements which thus indicate the unique suit for the diligence handling the delicate and brickle particulars.

Operations of Vacuum Conveying

Food and Beverage Industry: The Vacuum conveyors the major player of the food and libation assiduity icing delicate running of maquillages, grains, and other constituents. thus, we’ve maintained traceability in the force chain, which we support with applicable quality control measures.

Pharmaceuticals: Vacuum Conveying Systems are able to ensure that there was no impurity in pharmaceutical products, which are thought to be flawless, with hygiene being the main factor. during the material transfer. This is particularly important for the upholding of the ecological chastity of the product.

Chemical Processing: Vacuum Conveying: This technology works with chemical stores to allow mufflesafe transportation of vibrant chemical mixtures. A unrestricted layout system involves the use of wearing PPE which further minimizes the chances of exposure as well as shielded the workers.

Plastics Manufacturing: Vacuum running is pivotal in plastics manufacturing as it mechanizes and facilitates transport of plastic grains and greasepaint thus the mortal running isn’t involved presently. The advantage then’s that it increases the functional effectiveness and accordingly reduces the chances of mixing different accoutrements in an unwanted circumstance.

Bulk Material Handling: Bulk accoutrements openings for illustration cement, minerals, and summations are taken advantage of by diligence with vacuum conveying as a result of the capacity of high volume they have. It makes material movement more precise, significantly perfecting processes’ effectiveness.

Pharmaceutical Tablet Press Loading: Vacuum Conveying systems are used in pharmaceutical product lading of tablet press in such a way as to guarantee lozenge delicacy that allows both maquillages and grains to feed rightly in order to carry out the manufacturing process rightly.

Packaging Industry: Vacuum Conveying is used in the packaging assiduity for the rail effective material transfer. This applies inversely to transportations of everything used in fabricating different accoutrements of packaging.

Plastic Resin Conveying: For plastic resin directors the Vacuum Conveying systems have come an effective and dust free transfer system of plastic service, a factor that improves working terrain.

Metal Powder Handling: Companies which work with essence in fine form, like those in 3D printing or metallurgy, consider Vacuum Conveying as a result accurate and well controllable for moving similar material.

Woodworking: Vacuum Conveyor systems are the recent trend of manufacturing and operation diligence; previous to their wide use dust and sawdusts were discharged into the terrain. therefore, caused the community and safety hazards. But with the arrival of eco-friendly conveyor systems the mentioned issues were put to an end.

Advantages of Vacuum Conveying:

Vacuum Conveying is highly esteemed in numerous regions due to its versatility and the multitude of advantages it offers in material transfer processes.

Material Integrity: The suctioning process is simple and therefore the content material declination can be minimized. As a result, the process of Vacuum handling may be used to handle delicate or precious particulars.

Dust-Free Operation: A circle system guarantees an extraneous material transfer process, helping to count dust thereby making the working terrain cleaner and safer.

Customized Designs: In a variety of applications, vacuum conveying technology may be adapted to fulfill specific material conveying needs. This in turn enhances strictness among various artificial operations.

Reduced Manual Handling: The use of Vacuum Conveying for material transfer eliminates the need for the manual handling thereby, workers are guaranteed safety and lower effectiveness.

Contamination Control: Industriousness with specific quality specifications, for case, in medicinal and food processing fields are prone to the advantage of at home Vacuum handling.

High-Capacity Transport: Large material quantities may be handled by vacuum conveying systems, which makes them appropriate for a labor-intensive industry that uses this material moving technology for high-volume material transportation.

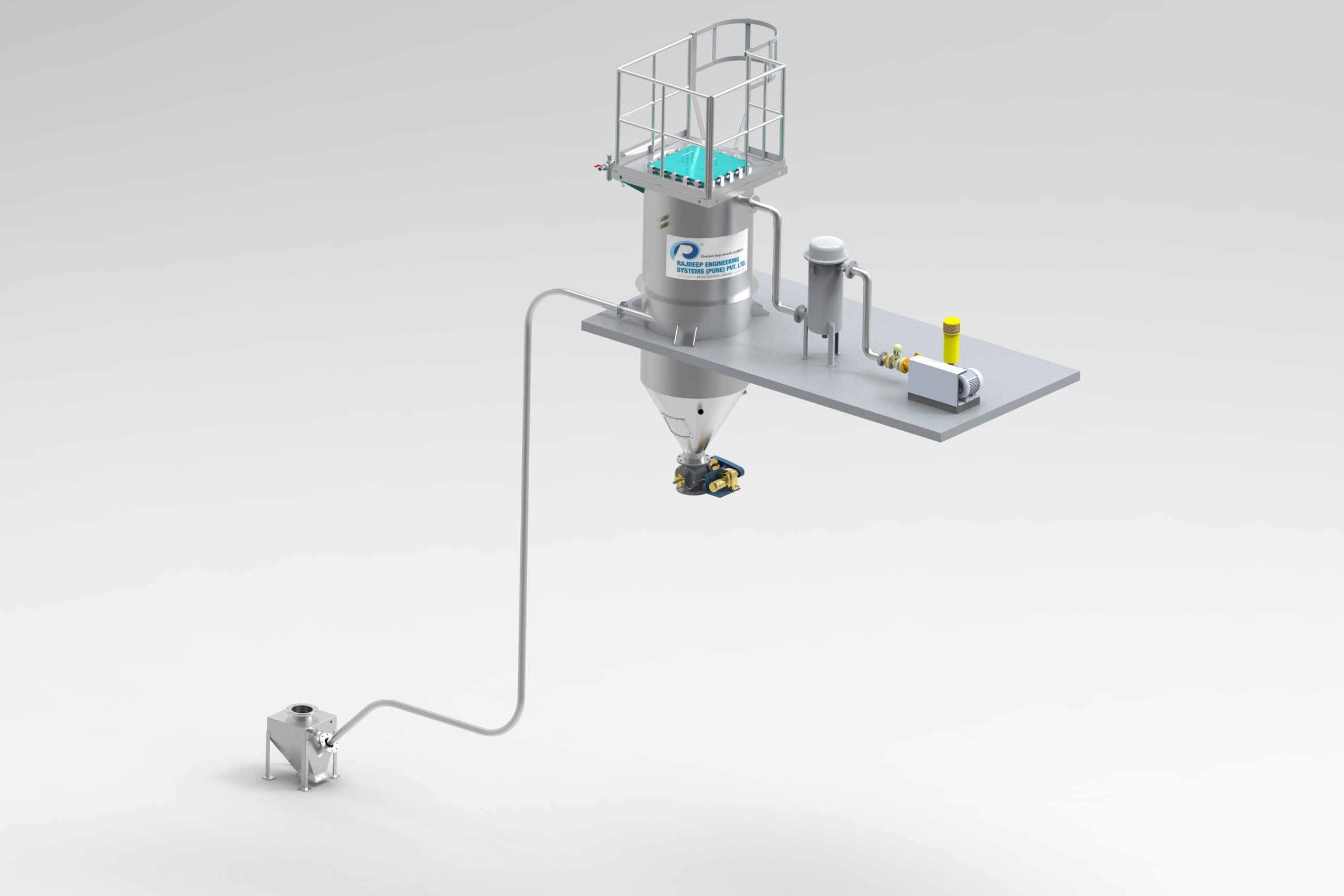

Key Components of Vacuum Conveying Systems

It’s necessary to know the vital pieces that make these types of systems exploitable to understand how the Vacuum Conveying functions.

Vacuum Pump: As it circulates the resources required for material movement, the vacuum pump, the system’s central component, produces suction.

Conveying Line: Material conduits of the channels are offered in a broad range of paraphernalia that suited riding conditions of different operation areas.

Material Pick- Up Points: These are located at the doors of the material to effect proper feeding of the conveying medium.

Filters and Separators: These factors could be a sludge and an input dust joker, which would stop the adulterants or dust from getting into the vacuum impeller, thereby easing free operation.

Receivers: All Innovative approaches including lockers or points where paraphernalia are collected at the destination point.

Control Systems: Sophisticated control systems supervise the entire Vacuum running process giving the swish performance rate versus cost. The protection of people and outfit is consummate.

Pressure Controls: These bias coordinate the pressure masteries, allowing instant and exact control of the transportation course.

Release Gates: Installed at specific locales in a way to release strain and confirm the material to the pace of the conveying.

Material Feed Devices: A rotary cock or a feed hopper provides the control of material inside of the conveying system setup.

Secondary Filtration Systems: Fresh adulterants to guarantee the chastity of conveyed paraphernalia, an structure thatnon- fail in sectors of industriousness that have strict cleanliness conditions.

Knowing fluently all factors’ places allows us to visualize how everything is tied together and works correctly in Vacuum Conveying systems.

Vacuum handling represents a huge technological feat in the material handling sedulity, a field fastening on moving paraphernalia from one position to another. Vacuum Conveying is not only applied to different industriousness but also considered to bring down material contamination, and dust-free operation to turn disastrous cases into studies. also, proper vehicle means proper operation of the process, and easy carrying of indeed small material volume. The sustainability of industriousness requires the elaboration of technologies and with it, the severity and effectiveness of Vacuum transfer is being placed as a pivotal element of the optimization of material handling.

Pingback: Pneumatic Conveying Systems: Navigating the Dynamic of Airborne Efficiency